Cable tray

STANDARDIZATION

Cable Tray Systems:

Where reference is made to other publications, such reference shall be considered to refer to the latest edition and all amendments published to that edition up to the time when this Standard was approved.

Canadian Standards Association (CSA):

5060 Spectrum Way, Suite 100 Mississauga, ON, Canada L4W 5N6

C02- 22.1 Canadian Electrical Code, Part I

CAN/CSA-G-164M92 (R1998) Hot Dip Galvanizing of Irregularly Shaped Articles

National Electrical Manufacturers Association (NEMA):

1300 North 17th Street Rosslyn, Virginia 22209 VE 2000-2 Cable Tray Installation Guidelines

American National Standards Institute (ANSI):

11 West 42nd Street New York, NY 10036 ANSI/NFPA 2002-70 National Electrical Code

American Society for Testing and Materials (ASTM):

1916 Race Street Philadelphia, PA 19103

A 123/A 123M01- a Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

A 653/A 653M02- Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc- Iron Alloy-Coated

(Gal annealed) by the Hot-Dip Process

B 98-633e1 Standard Specification for Electrodeposited Coatings of Zinc on Iron and Steel

MATERIALS

Aluminum

Aluminum cable trays are fabricated from structural grade (marine grade) aluminum extrusions. Aluminum’s excellent corrosion resistance is due to its ability to form an aluminum oxide film that when scratched or cut reforms the original protective film. Aluminum has excellent resistance to “weathering” in most outdoor applications. Aluminum cable tray has excellent corrosion resistance in many chemical environments, aluminum cable trays can perform indefinitely, with little or no degradation over time, making it ideal for many chemical and marine environments. The resistance to chemicals, indoor and outdoor, can best be determined by tests conducted by the user with exposure to the specific conditions for which it is intended. For further information, contact EISCO.

Steel

Steel cable trays are fabricated from continuous roll-formed structural quality steel. By roll-forming steel, the mechanical properties are increased allowing the use of a lighter gauge steel to carry the required load. This reduces the dead weight that must be carried by the supports and the installers. Using Structural quality steel, EISCO assures that the material will meet the minimum yield and tensile strengths of applicable ASTM standards. All cable tray side rails, rungs and splice plates are numbered for material traceability. The corrosion resistance of steel varies widely with coating and alloy.

Stainless Steel

Stainless Steel cable trays are fabricated from continuous roll-formed AISI Type 304 or AISI Type 316/316L stainless steel. Both are non-magnetic and belong to the group called austenitic stainless steels. Like carbon steel, they exhibit increased strength when cold worked by roll-forming or bending. Several important conditions could make the use of stainless steel imperative. These include long term maintenance costs, corrosion resistance, appearance and locations where product contamination is undesirable. Stainless steel exhibits stable structural properties such as Yield strength and high creep Strength at elevated temperatures. EISCO’s stainless steel cable trays are welded using stainless steel. Welding wire to ensure each weldment exhibits the same corrosion resistant characteristic as the base metal. Localized staining in the weld area or heat affected zone may occur in severe environments. Specialized shielding gases and low carbon materials are used to minimize carbon contamination during welding and reduce staining and stress corrosion. Specify passivation after fabrication per ASTM A380 to minimize staining, improve aesthetics and further improve corrosion resistance.

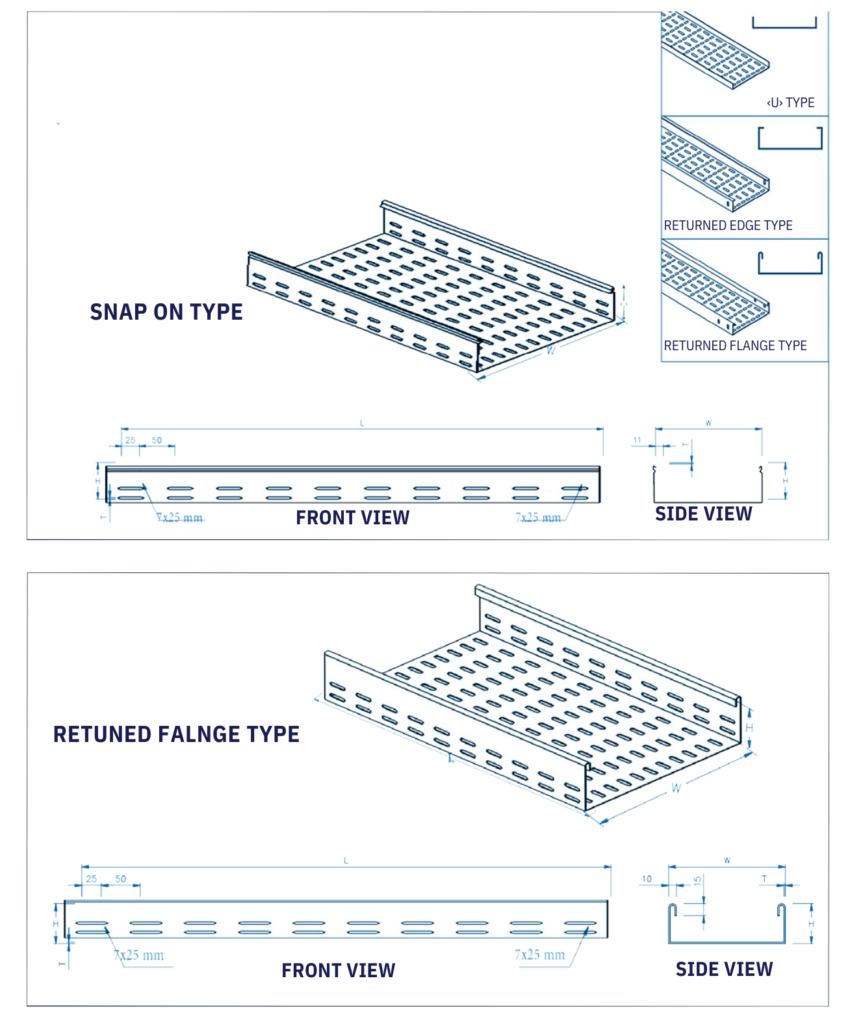

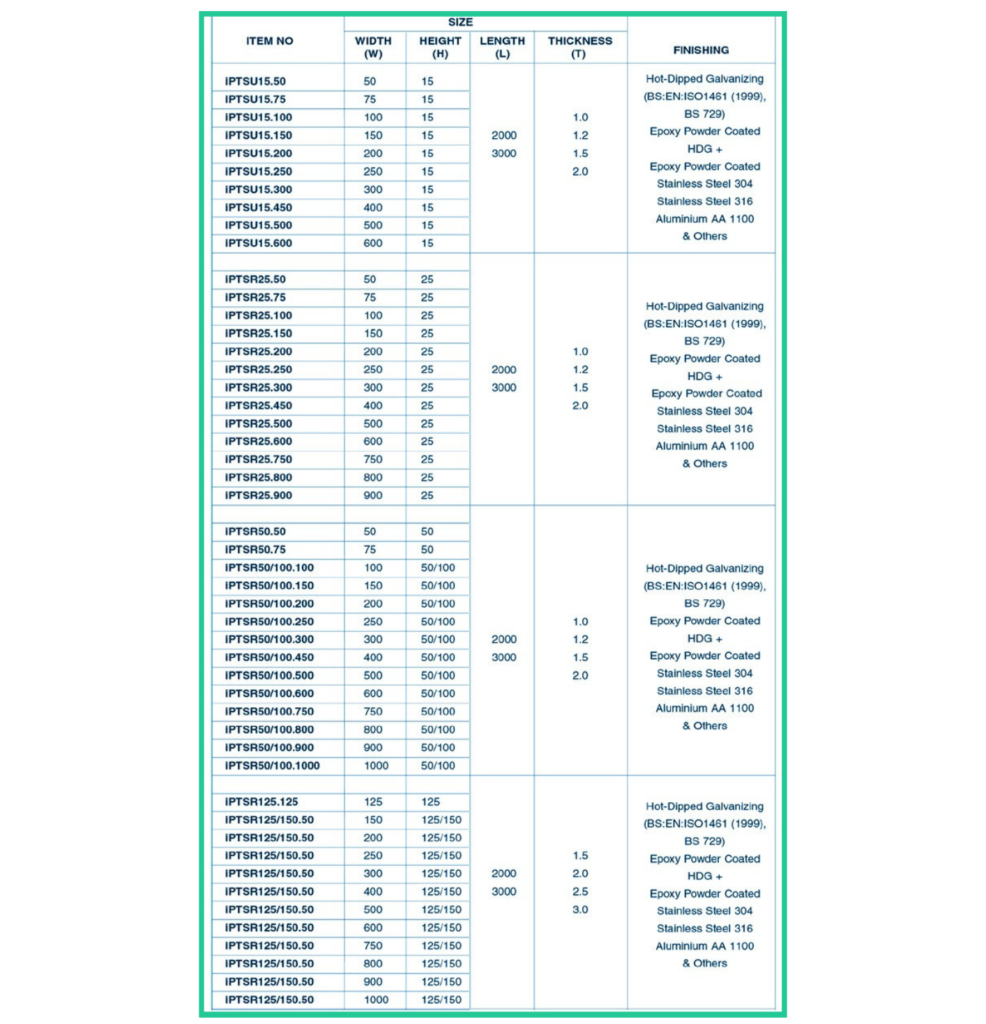

STRAIGHT PERFORATED TRAY

STANDARDIZATION

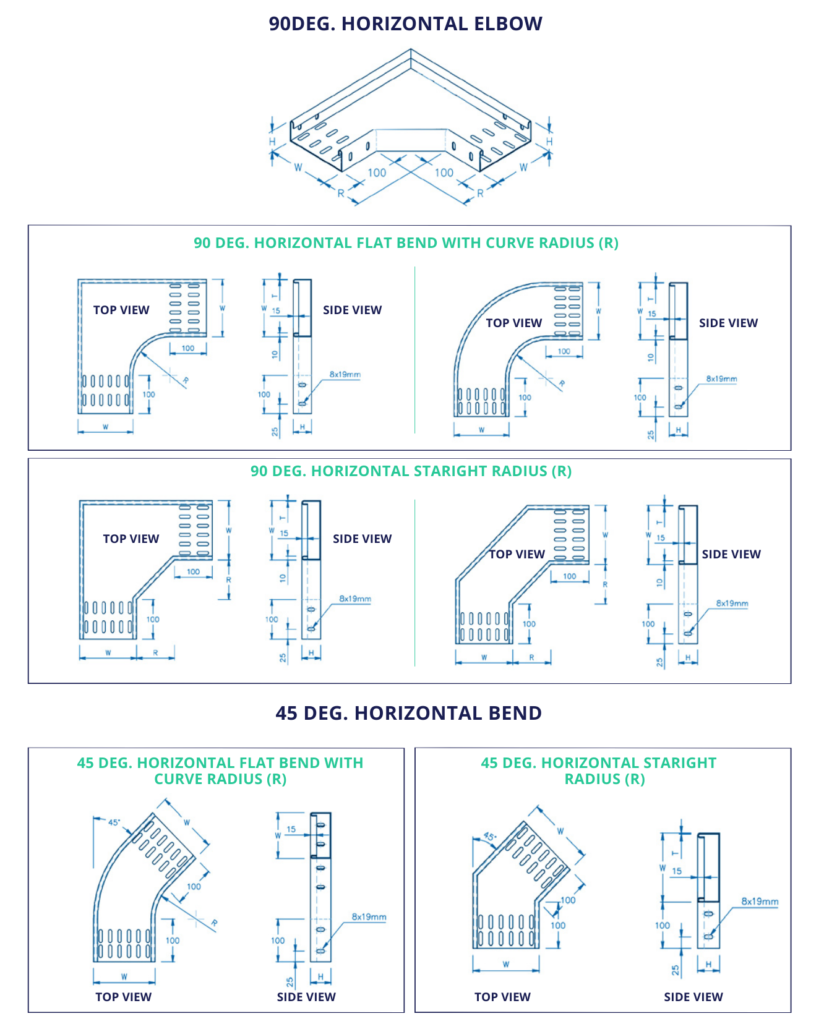

HORIZONTAL ELBOW

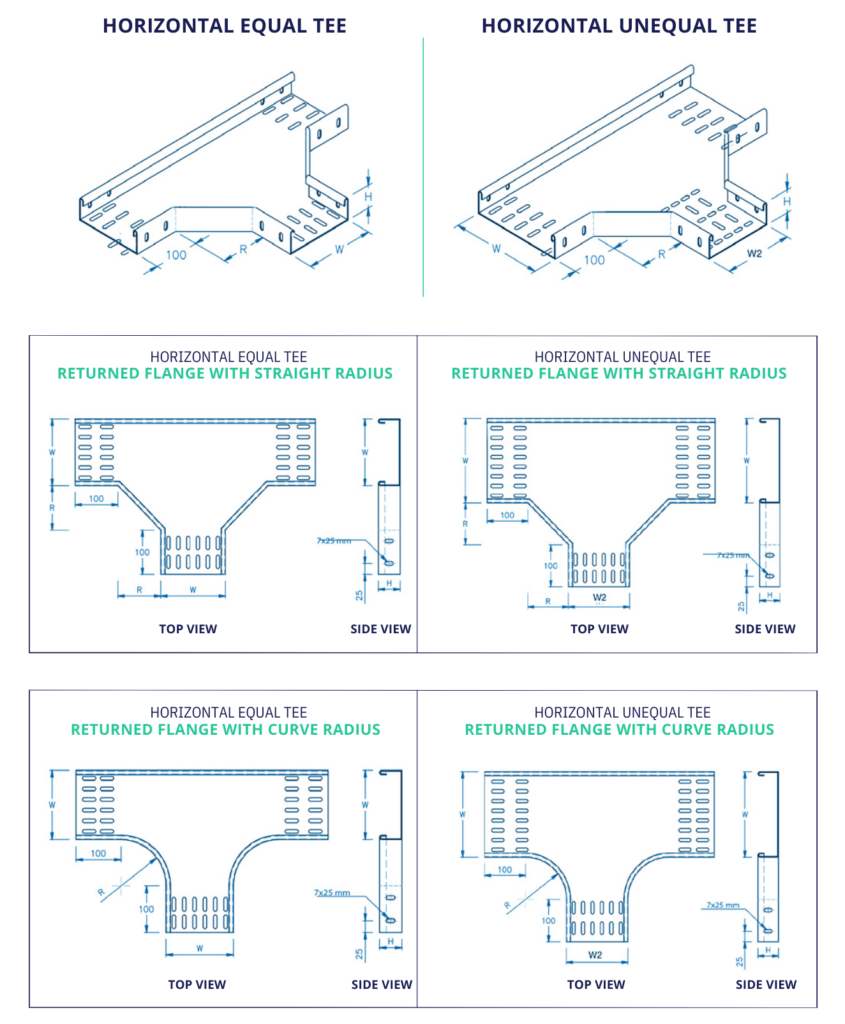

HORIZONTAL TEE

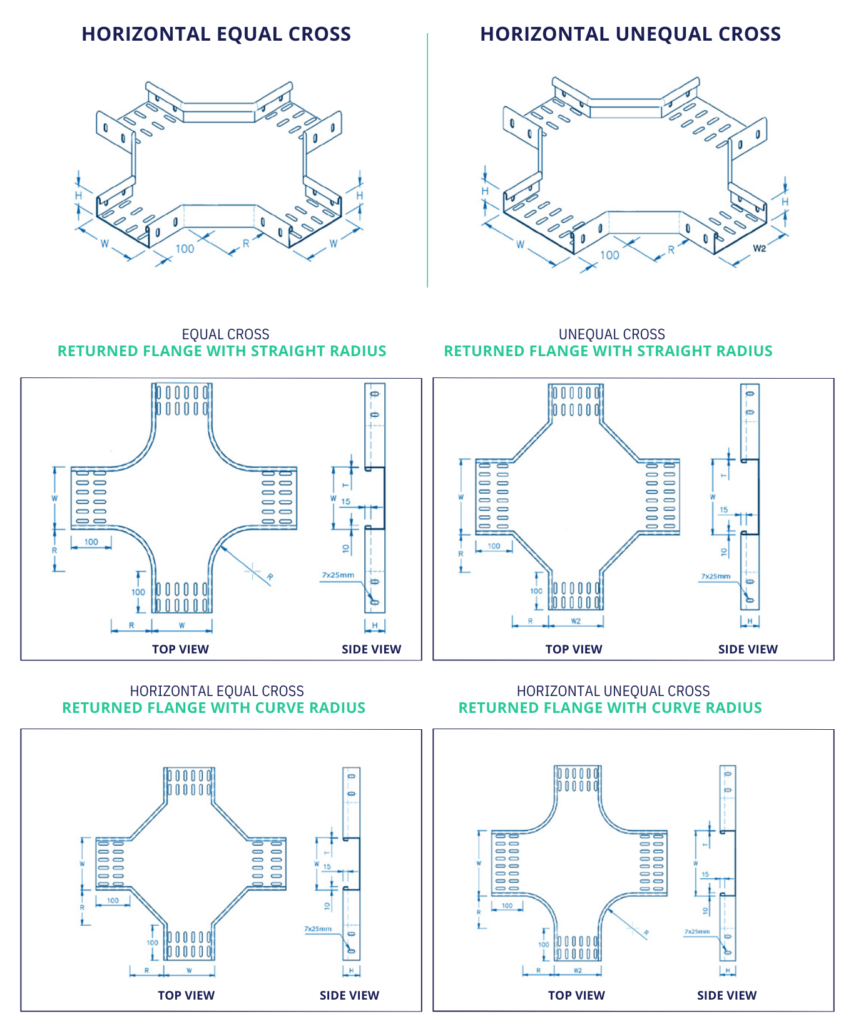

HORIZONTAL CROSS

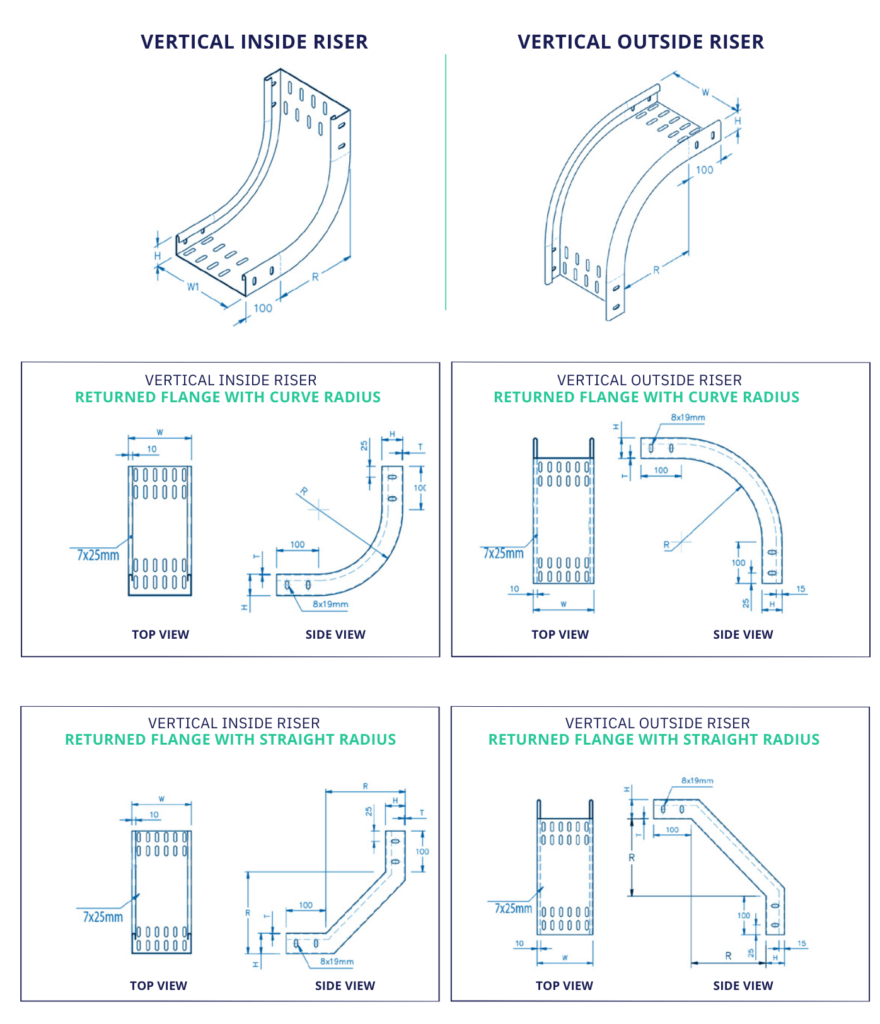

VERTICAL RISER

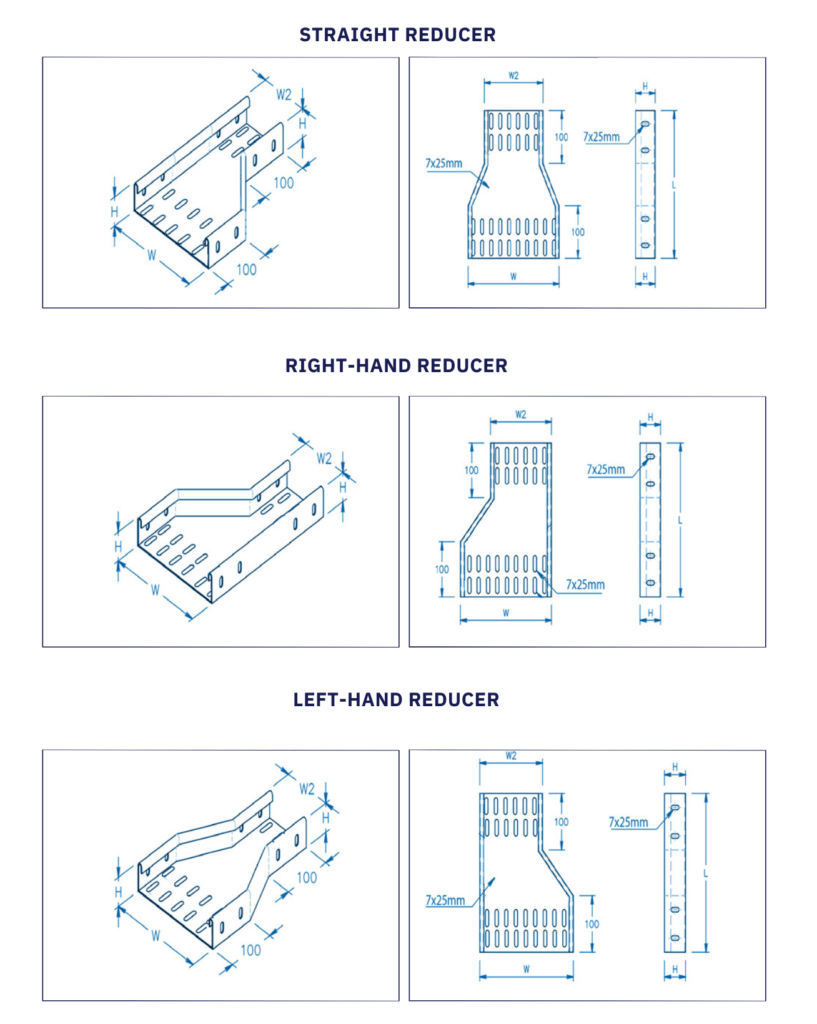

OFFEST REDUCER